| Background | | | Product | |||||||||

| Overview | | | Features | | | System architecture | | | Specifications | | | Use Cases | |||

The system is composed of a control panel equipped with a radio frequency identification (RFID) tag reader and keypad, a wireless sensor network, a wireless meter data acquisition device, and RFID tags.

Wireless meter data acquisition devices are installed on water meters, electricity meters, steam flow meters, and yard meters throughout the factory to obtain accurate energy consumption data and real-time production status.

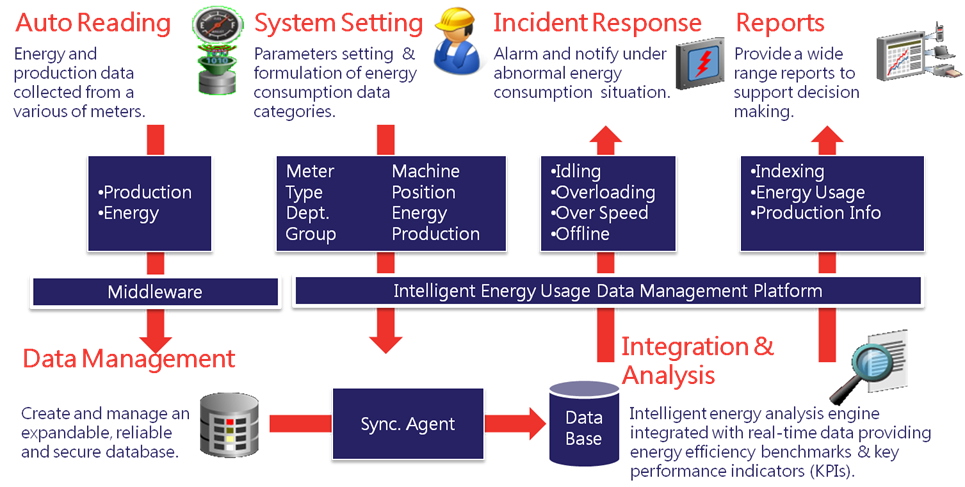

The data on energy consumption and production status of the shop floors are then transmitted to the back-end server for intelligence analysis through the wireless sensor network.

Before production starts, clerical workers key in new orders into the system and couple each with an RFID tag.

When the production begins, the cloth arrangement workers key in the quantity of goods issued using the control panels. The quantity of goods is instantly transmitted to the system.

At the beginning of each production process, operators wave their RFID tags over the control panel to record the time that each product takes to reach the assigned production and handling operator. The production status of goods is then immediately transmitted to the system.

After the completion of the process, operators wave their RFID tags over the control panel again to record the completion time of the process, the quantity of goods, and the person handling the process. The production status is immediately transmitted to the system.

Then, the system records the energy consumption and production status of every production order. Through establishing the energy consumption indicators by intelligence analysis, the system provides managers energy-saving targets for reference and accurate real-time production information.